High quality 3-coil DC9v-12V-24v-36V 5W/10W/15W mobile phone wireless quick charging for truck bus BUS(Accept customization)

Product Description :

1 Electrical Specification

1.1 Transmitter Module Unit Summary

1.1.1 Input voltage : 9V-12V-24V-36V

1.1.2 Rated input current: 0-2A(Max 2A)

1.1.3 Required input Ripple voltage: <150mVp-p @ 3A 12V

1.1.4 Fast Wireless Output power of Rx: 15W (9V1.1A)

1.1.7 Switching frequency: Working For QI 110-205KHZ,IPhone fast charging 127.7 KHZ

1.1.8 Wireless Charging Efficiency >75% (IDT P9221-R-EVK Tester )10W

1.1.9 Wireless charger Standby current <35mA 12V

1.1.10 Charging Distance :3-8mm(+/- 1mm)

Ambient operating Temperature: -10 to 45℃

1.1.12 Over current protection: 2A(wireless charger inside protect)

1.1.13 Thermal protection: 90℃(wireless charger inside protect)

1..1.14 Operating Temperature:0℃ to 35℃

1..1.15 Storage Temperature:-20℃ to 80℃

1..1.16 Operating Humidity:10% to 70% RH

1..1.17 Storage Humidity:10% to 80% RH

1.1.18 Effective Charging Area: typ. +/-5mm from coil centre (Dz=3mm)

1.1.19 Effective Charging Distance: typ.+3~ +6mm from Tx-coil to Rx-coil

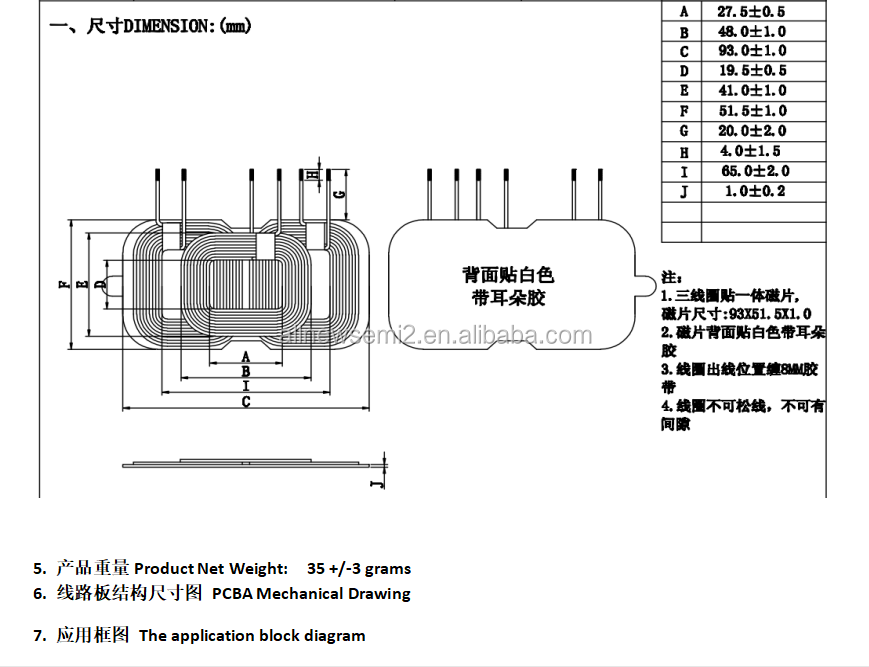

1.2 Coil Module Unit

1.2.1 Power Coil Inductance: 6.5uH +/-10%

1.2.2 Power Coil Resistance, DC: <50m ohm

1.2.3 FOD FOD Coil Inductance: 4.5uH +/-10%

1.2.4 FOD FOD Coil Resistance, DC: <280m Ohm

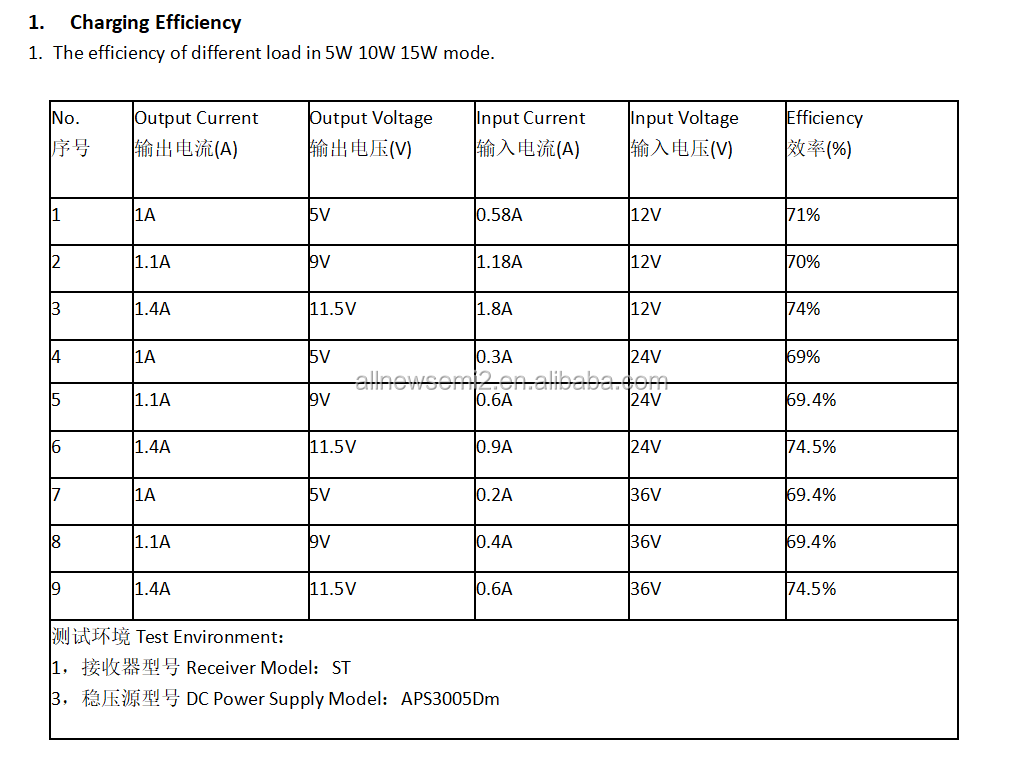

1 Wireless Charger Output Characteristics

Output Characteristics (The output voltage, output current meets the following criteria)

Input Voltage/Current(Input Tolerance ±5%)

1. Stand by :

12V0.03A

24V0.01A

36V0.01A

2. RX 5W mode

12V0.58A

24V0.3A

36V0.2A

3. RX 10W mode

12V1.18A

24V0.6A

36V0.4A

4. RX 15W mode

12V1.8A

24V.9A

36V0.6A

3. Testing temperature

In the case of maximum voltage 36V output, test the maximum temperature of components for wireless charging 5W and 10W output for 1 hour.

1. Wireless receiver loader 9V1.1A 10W for 1hour max temperature on buck IC 84℃. ( environment temperature 28℃)

2. Wireless receiver loader 5V1A 5W for 1hour max temperature on buck IC 57℃. ( environment temperature 28℃)

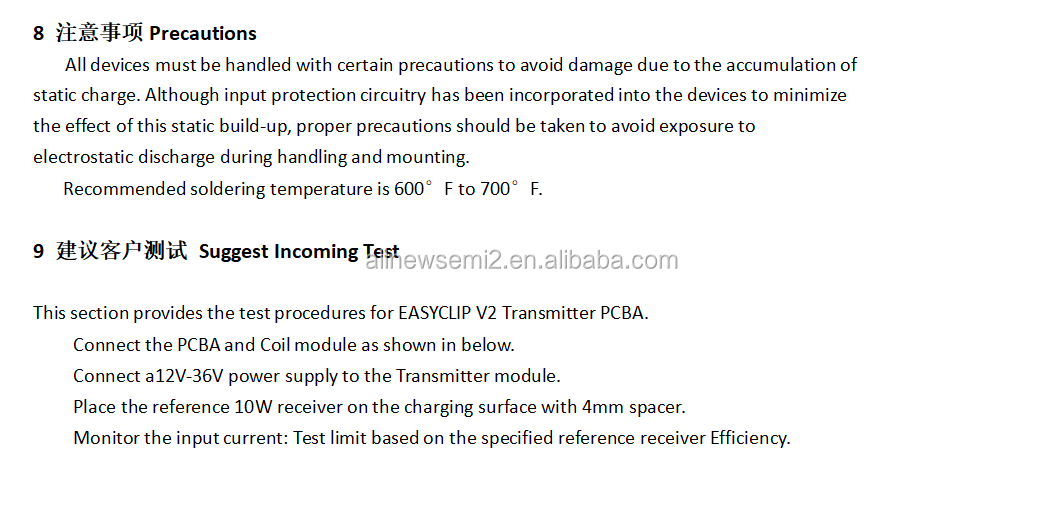

2.2.2 Over Current Protection

After triggering the over current protection, the transmitter stops working and the transmitter will return to normal operation when the receiver is removed.

2.2.3 Over Temperature Protection

The control temperature of the transmitter is above 90℃ or external NTC temperature above 90℃, the transmitter to stop working, the temperature dropped to normal conditions, five minutes later, the transmitter back to normal work.

2.2.4 Parasitic Metal Object Detect

When the transmitter coil is detected the metal larger than the coin size , the transmitter stops working,and the transmitter returns to normal working after the metal is removed.

2.2.5 Foreign Object Detect

In the case of the normal work of the transmitters and receivers, the coin size metal is inserted between the transmitting coil and the receiving coil. The transmitter must be stopped within 2 minutes (the receiver protocol version requires WPC1.1 or above).

2.2.6 (VRVS)Vertex Shutdown (VRVS)

In the case of the normal work of the transmitters and receivers, receiver coil position relative to the transmitter coil displacement , causes transmitter coil over voltage,and transmitter must enter the current limit mode, in order to protect the transmitter.

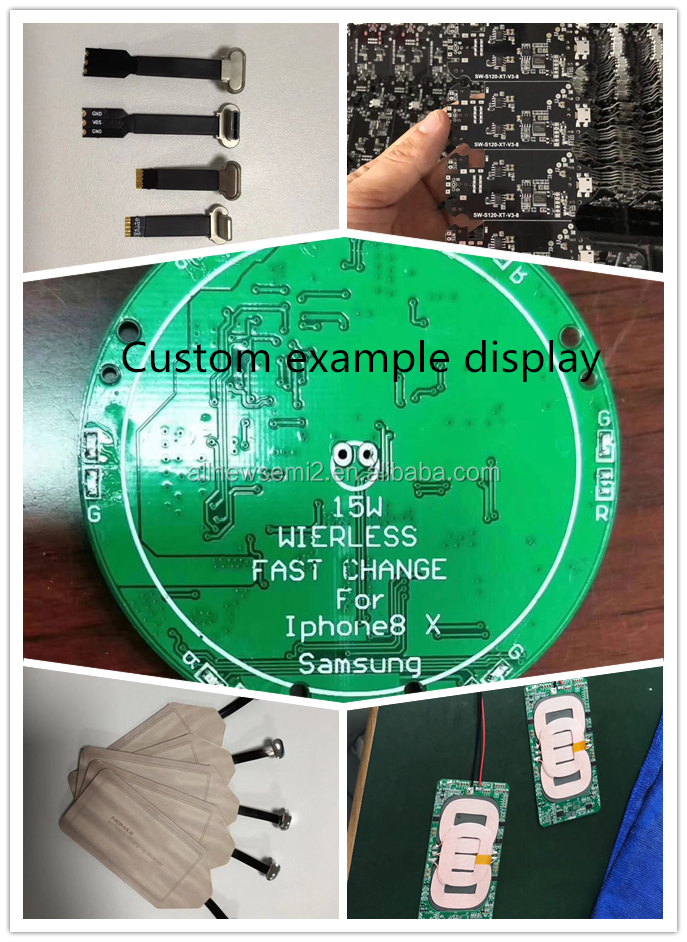

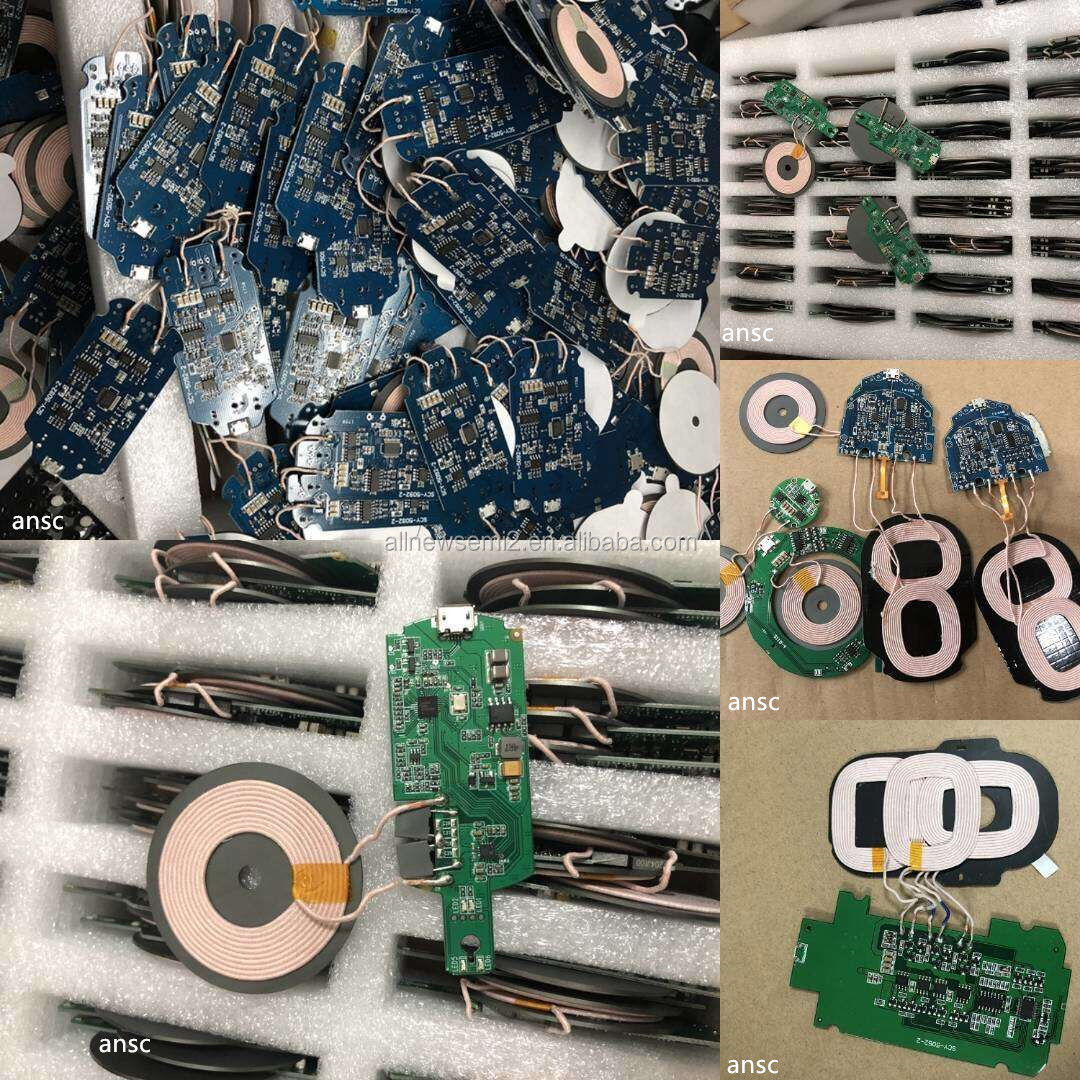

How to get a custom type wireless charging and transmitting module quote:

| 1.What machine to use |

| 2. Input voltage + current |

| 3. Output voltage + current |

| 4. Shape + size requirements |

| 5. Coil requirements (1 coil? 2 coils? 3 coils or ..?) |

| 6. Plug / Welding wire Detailed requirements |

| 7. Quantity |

| 8. Certification requirements |

| 9. Other requirements |

This is a customized product, please contact us for price and more details.

Exhibition

Advantages

FAQ